WP 101 High Grade Polyurethane Waterproof Coating

Applications

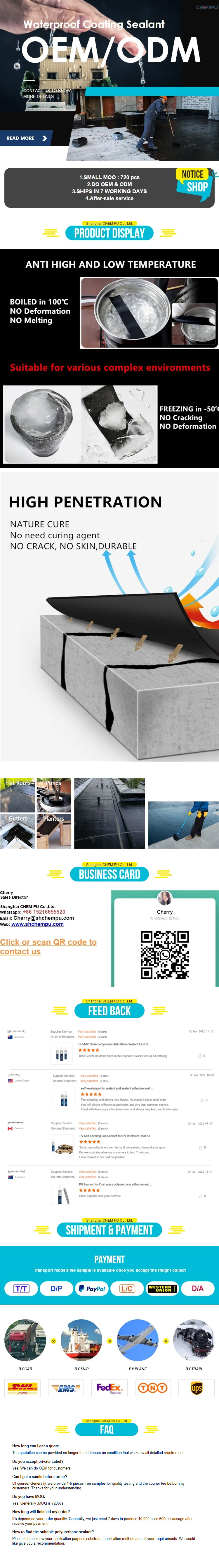

It is used for external and internal application on concrete, cement boards, metal roofs, etc.

Waterproofing for basement, kitchen, bathroom, underground tunnel, deep wells structure and normal decoration.

Car Parking Areas, External Building Walls/ Facades, etc.

Bonding and moisture-proofing of various floor tiles, marble, asbestos plank,etc.

Warranty and Liability

All product properties and application details based on information are ensured to be reliable and accurate. But you still need to test its property and safety before application.

All advices we supply can’t be applied in any circumstances.

CHEMPU don't make assurance of any other applications outside the specification until CHEMPU supply a special written guarantee.

CHEMPU is only responsible to replace or refund if this product is defective within the warranty period stated above.

CHEMPU makes it clear that will not take responsible for any accidents.

Technical Data

|

PROPERTY WP101 |

|

|

Appearance |

Grey Uniform Sticky Liquid |

|

Density (g/cm³) |

1.35±0.5 |

|

Tack Free Time (Hr) |

4 |

|

Elongation at break |

600±50% |

|

Tensile Strength (N/mm2) |

7±1 |

|

Tear Strength(N/mm2) |

30-35 N/mm2 |

|

Hardness (Shore A) |

60±5 |

|

Elongation at Break (%) |

≥1000 |

|

Solid Content (%) |

95 |

|

Curing Time( Hr) |

24 |

|

Crack bridging capability |

>2.5 mm ℃ |

|

Shelf Life (Month) |

9 |

|

Implementation of standards: JT/T589-2004 |

|

Storage Notice

1.Sealed and stored in cool and dry place.

2.It is suggested to be stored at 5~25 ℃, and the humidity is less than 50%RH.

3.If the temperature is higher than 40 ℃ or the humidity is more than 80%RH, the shelf life may be shorter.

Packing

500ml/Bag, 600ml/Sausage, 20kg/Pail 230kg/Drum

The substrate should be smooth, solid, clean, dry without sharp concave and convex points, honeycomb, pocking marks, peeling, free of bulges, greasy before application.

Construction instruction:

1.Construction times :2-3 times.

2.Coating thickness: 0.5mm-0.7mm every time

Apply a first coat of on primed surface as seamless film and let it dry for 20-24 hours. After the first coat has fully dried and set, apply a second coat in cross direction and let it cure for 3- 4 days (Re-coat time: min. 1 day & max. 2 days at @25 ℃, 60% R.H.).Recommended film thickness should be minimum 1.5 mm for exposed terrace waterproofing and 2.0 mm for human trafficable floors.

3.Application

1mm thickness coating per square meters need about 1.5kgs/㎡

1.5mm thickness coating per square meters need about 2kg-2.5kg/㎡

2mm thickness coating per square meters need about 3kg-3.5kg/㎡

4.Construction method: worker Brush, roller, scraper

4. Attention of operation

Wear suitable protective clothing, gloves and eye/face protection. After contact with skin, wash immediately with plenty of water and soap. In case of accident or if you feel unwell, seek medical advice immediately.